Systematic Energy and Resource Management

With a tailored energy and resource management system, companies can attain greater success in savings and can continually improve their efficiency.

Successful reduction in energy and resource usage is not only a question of the right technical measures, but also effective management. However, in many companies, there are several systems that run parallel and unconnected to one another. Kofler Energies starts here with a detailed analysis and develops customized management systems that produce reduced energy and resource usage or greater product quality.

Our evaluations in the energy sector show that companies who let their energy managers take charge of their own budgets lower their cost by an average of 8.3%. If, in addition, comprehensive process documentation was established and responsibilities clearly assigned, that number grew to 15.6%. Systems that were implemented according to Norm ISO 50001 are particularly profitable: according to an analysis by auditing firm PricewaterhouseCoopers, costs were reduced by approx. 25% on average.

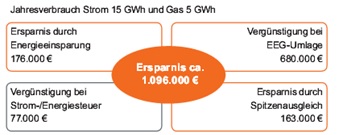

Potential savings by example of a company that used our consulting services

In addition to energy efficiency, sustainable use of raw materials is also becoming increasingly important. The German government has defined certain goals in its national strategy for sustainability regarding productivity of raw materials and, with its resource efficiency program ProgRess, aims to separate economic growth from resource consumption as much as possible.

Multistage Implementation Approach

Increasing energy and resource efficiency requires industry-specific, and therefore respectively different strategies. In general, we follow a multistage approach in the development of management systems:

Stage 1: Organizational analysis: By means of a SWOT analysis, we examine the current state of the company.

Stage 2: Implementation phase: We develop a course of action going forward as well strategic and operating goals. Workshops with the project team regarding the norms and system contents follow.

Stage 3: Certification phase: We support the company through further organizational training and a management review up to certification (DIN ISO 50001, DIN ISO 14001, DIN ISO 16247).

Stage 4: Operating phase: Through the startup of the management system, we introduce a continual improvement process (CIP).